Print Control - Introduction

Quality control is obviously essential to guarantee your customers the regularity and reliability of your proofs and your print production.

The printing controls are carried out using charts, standardized control ranges or personalized in CMYK, RGB or spot colors mode.

The standardized control ranges are published by professional organizations such as IDEAlliance, Ugra, Fogra, ECI and BvDM or provided by software publishers, such as EFI, GMG, etc. They are sometimes free but the more often paying (La Fogra for example).

These are mainly used in the field of Graphic Arts to control proofs printed according to ISO 12647-x standards.

The Print Control module

The aim of this module is to:

- Control CMYK BATs (Good To Draw) in the field of Graphic Arts, in order to validate compliance with reference standards FOGRA, UGRA, IDEAlliance, etc ...

- Control stability of your printer to avoid unpleasant surprises when printing. (RGB or CMYK)

- Check the quality after a calibration operation. (RGB or CMYK)

- Control the uniformity of prints between several printers (RGB or CMYK)

- Control the reproduction of your spot colors (PANTONE color charts, vinyl color charts, etc.)

- Control the test charts that will be used for the characterization of your offset or digital presses (RGB or CMYK)

- etc ...

The first step is to create the reference range

To generate your chart you can choose between creating a chart in RGB, CMYK or done with spot colors.

This module will allow you to create control ranges from colors coming from:

For more information, see the chapter: Creating a reference for proofing

- A measurement carried out on a reference print, to monitor the stability of a printer for example.

For more information, see the chapter: Creating a reference from a printed range

- A standard range, to carry out a more precise control or to control the ranges intended to be averaged to characterize production presses for example

For more information, see the chapter: Creating a reference from a printed chart

- A color chart of direct colors, to control the reproducibility of the colors of your PANTONE color charts for example.

For more information, see the chapter: Creating a reference from a spot color chart

- A color table, to customize and choose the colors you want to control

For more information, see the chapter: Create a reference from a custom RGB or CMYK color table

The second step is to measure the range generated previously

Each control measurement will be added to the reference file in order to keep a history of the measurements made to monitor the drifts of your printer.

So you can guarantee your customers the regularity of your impressions.

To find out more, see chapter: Controlling a CMYK Mediawedge range

The different types of ranges that can be used with Print Control:

1) Standard CMYK ranges to control proofs in the field of graphic arts

Coraye offers four types of ranges as standard:

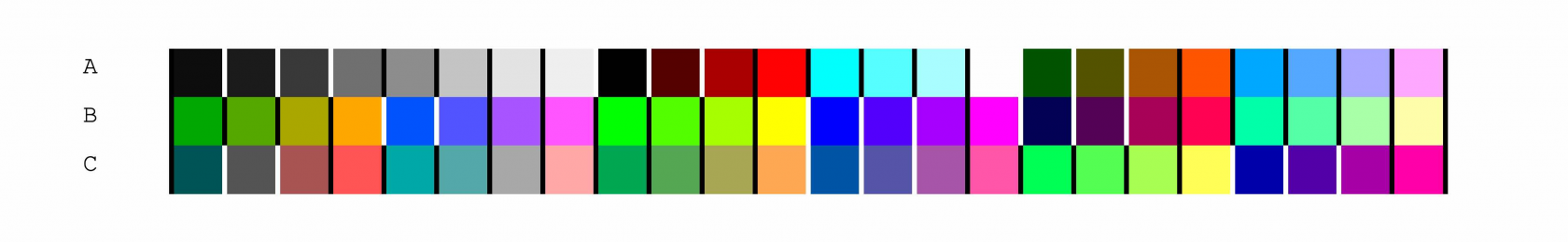

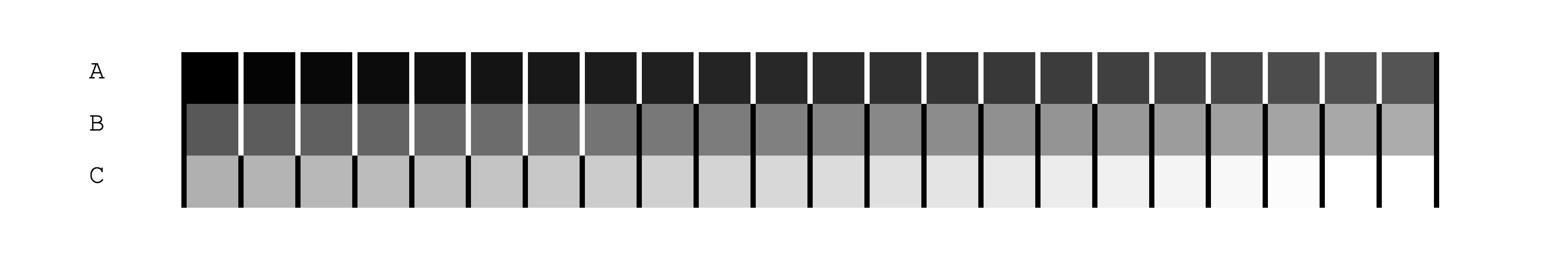

2) RGB ranges to control the stability and neutrality of your prints

3) The test charts offered as standard in the profiling module for more precise control of your prints.

-

ECI2002 CMYK (1539 patches)

-

ECI2002R CMYK (1485 patches)

-

IT8.7-3 CMYK (928 patches)

-

IT8.7-4 CMYK (1617 patches)

-

TC 3.5 CMYK (432 patches)

-

TC918 RGB (918 patches)

-

TC2.83 RGB (294 patches)

-

etc ...

4) The test charts generated from the spot color tables in order to check the accuracy when reproducing your PANTONES or your other color charts.

Spot color control requires the use of a RIP that supports spot color management such as PANTONEs.

If you use custom spot colors, you must first add the colors you want to check and control, in the RIP color chart.

5) Personalized test charts created from Coraye color tables

For more information, see the chapter: Create a reference from a custom RGB or CMYK color table

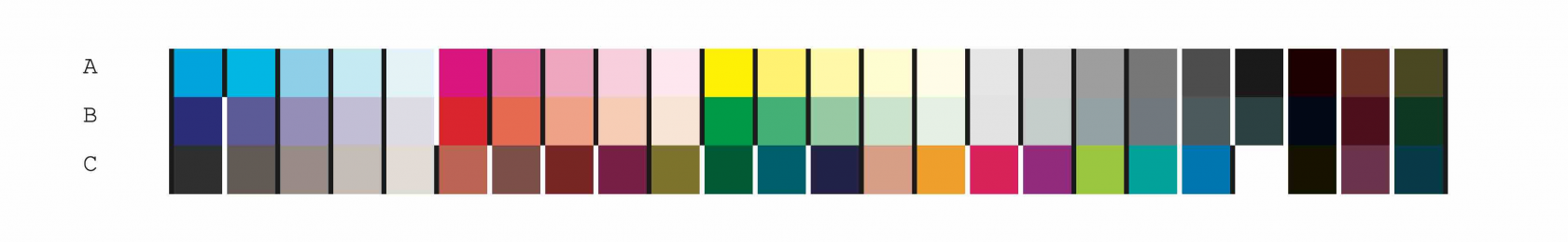

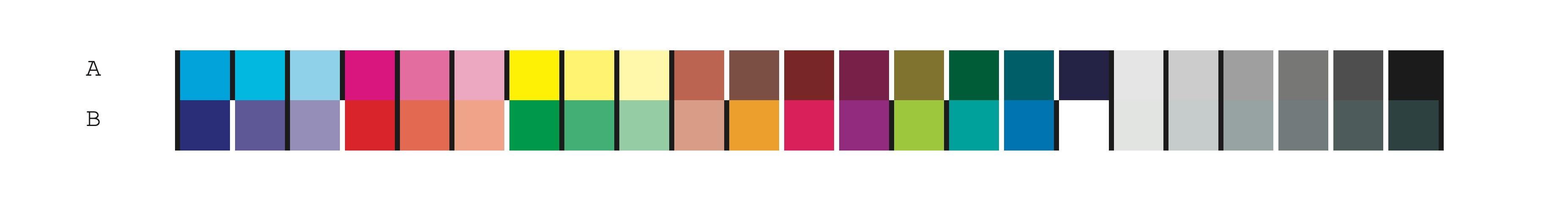

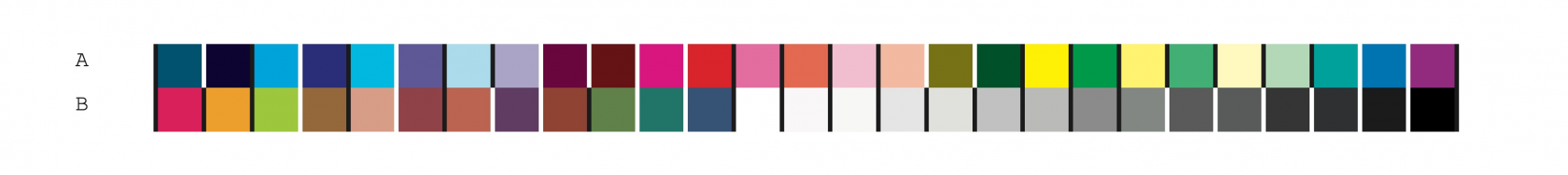

Mediawedge 72 patches Fogra

Mediawedge 72 patches Fogra IDEAlliance 84 patches

IDEAlliance 84 patches Mediawedge 46 patches Fogra

Mediawedge 46 patches Fogra IDEAlliance 54 patches

IDEAlliance 54 patches Mediawedge RGB

Mediawedge RGB Mediawedge Gray RGB

Mediawedge Gray RGB